Finally, we are well aware of the importance of safe and prompt delivery. We can provide fast and reliable delivery services through our computer-based barcode system, two warehouses with a total capacity of 34.000 pallets and a fleet of trucks. Korozo also uses logistic companies for local and worldwide consignments.

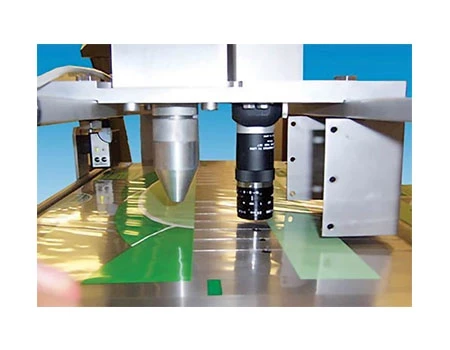

Korozo has laser scribing and perforation technologies, these can perform: Laser scribing, micro and macro perforation.

Korozo has the manufacturing capability to produce all types of laminated slitted reels, stand up pouches, carrier bags.

Korozo has 11 lamination lines to prevent food contact with the ink, to decrease oxygen permeability, eliminate light when necessary and to increase the aesthetics of the packaging. Layers of films are combined together for final processing of films used in automatic filling machines, three-sided sealed vacuum bags and stand up pouches.

Our rotogravure equipment can print up to 11 colours to a maximum 1380mm width. Cold seal, lacquer and also in-line lamination applications are available in rotogravure, which is widely used in food packaging.

Our high-tech flexo machines can print up to 10 colours and 1570mm printing machinery. Korozo also provides flexo printing with a rotogravure unit.

Korozo’s inhouse rotogravure department makes excellent operations of surface finishing cylinder engraving and press proofing to provide its customers faster and more effective service.

Once your designs are ready to print, they are transferred to our plate making departments for Ultra HD Flexo plate making, inhouse CTP plate making.

Our experienced staff will check your designs before going to press or you can leave the creative stuff to us. Requests for amendments and modifications are catered for as part of the service.

We know colour is crucial for brand image and stand out shelf appeal. At Korozo we operate three separate in house ink dispensing systems for exceptional flexo and rotogravure print results.

Korozo’s customer-oriented Film Extrusion Department produces LDPE, LLDPE, MDPE, HDPE, PP, Barrier type blown films and cast stretch film on its 3, 5, 7 and

9-layer co-extrusion lines with support from experienced R&D, design and field services teams.